One Platform to "Harness Your DATA"

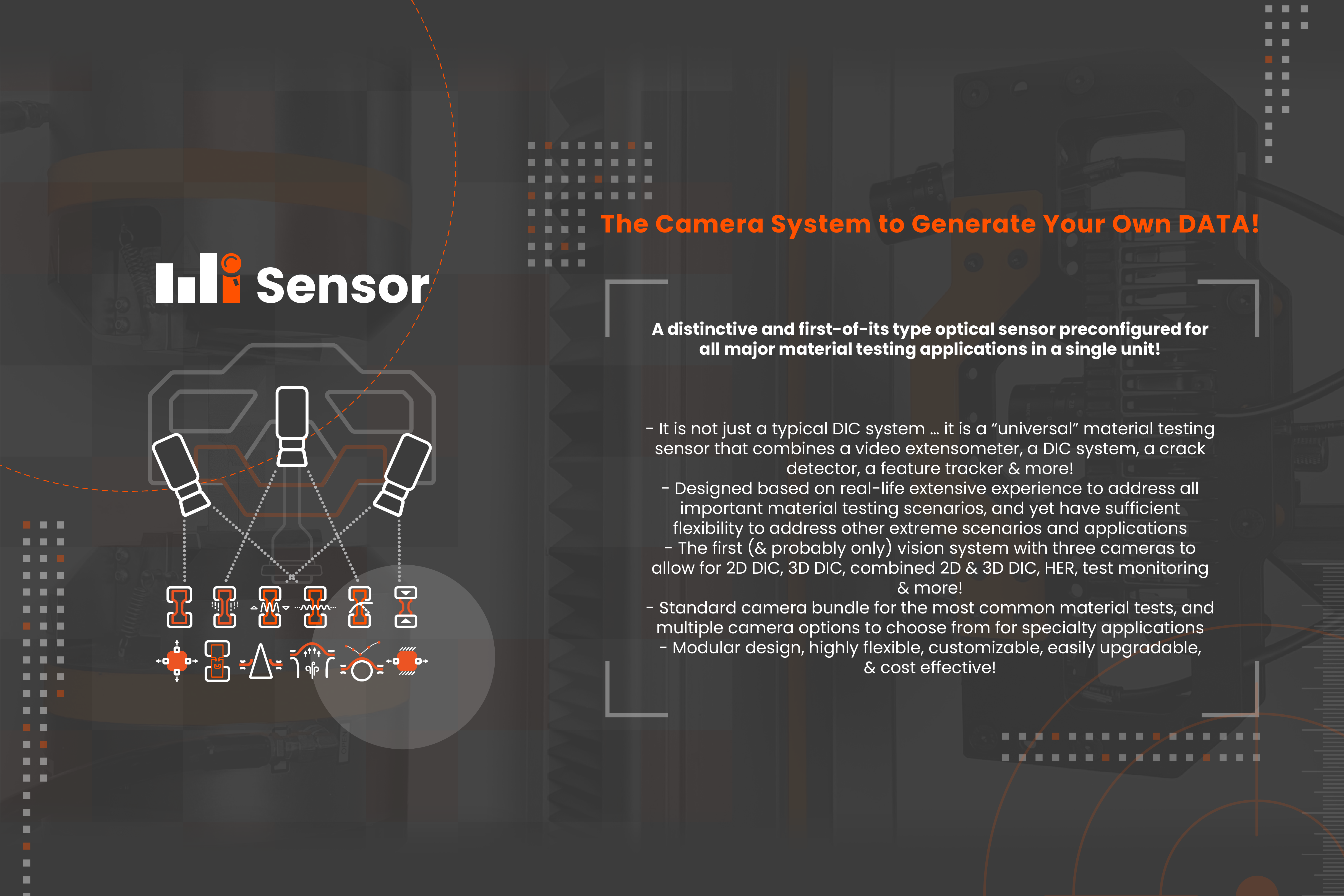

“material insights” by FADI-AMT is a unique platform of products all cohesively integrated to provide you access to high quality R&D level “Material DATA” … All the products are derived from and based on extensive experience, thorough understanding, and passion about material deformation & failure!

Why Our DATA?

The DATA we offer is simply unique and on a totally different level … we call it “mi-DATA”!

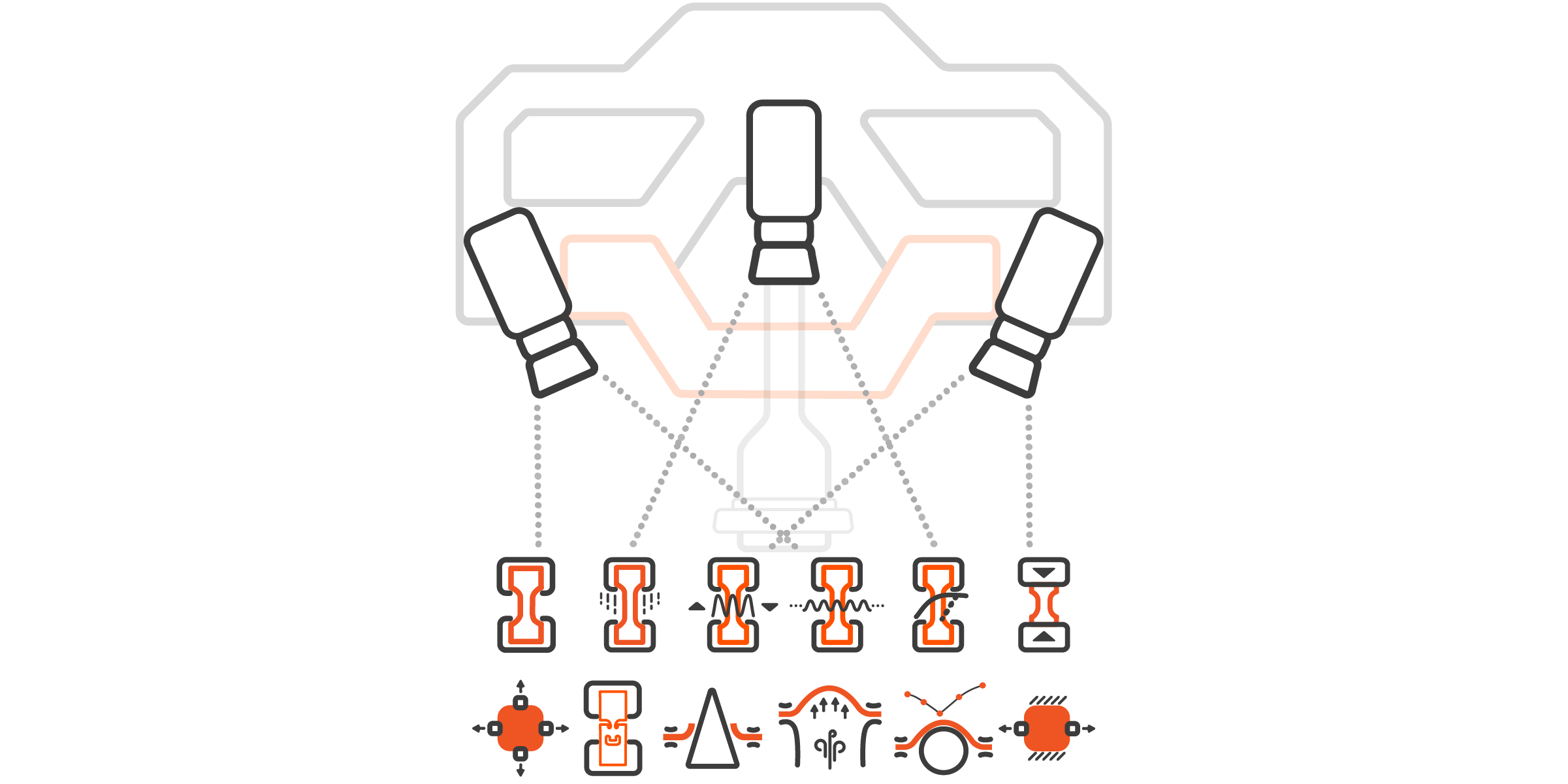

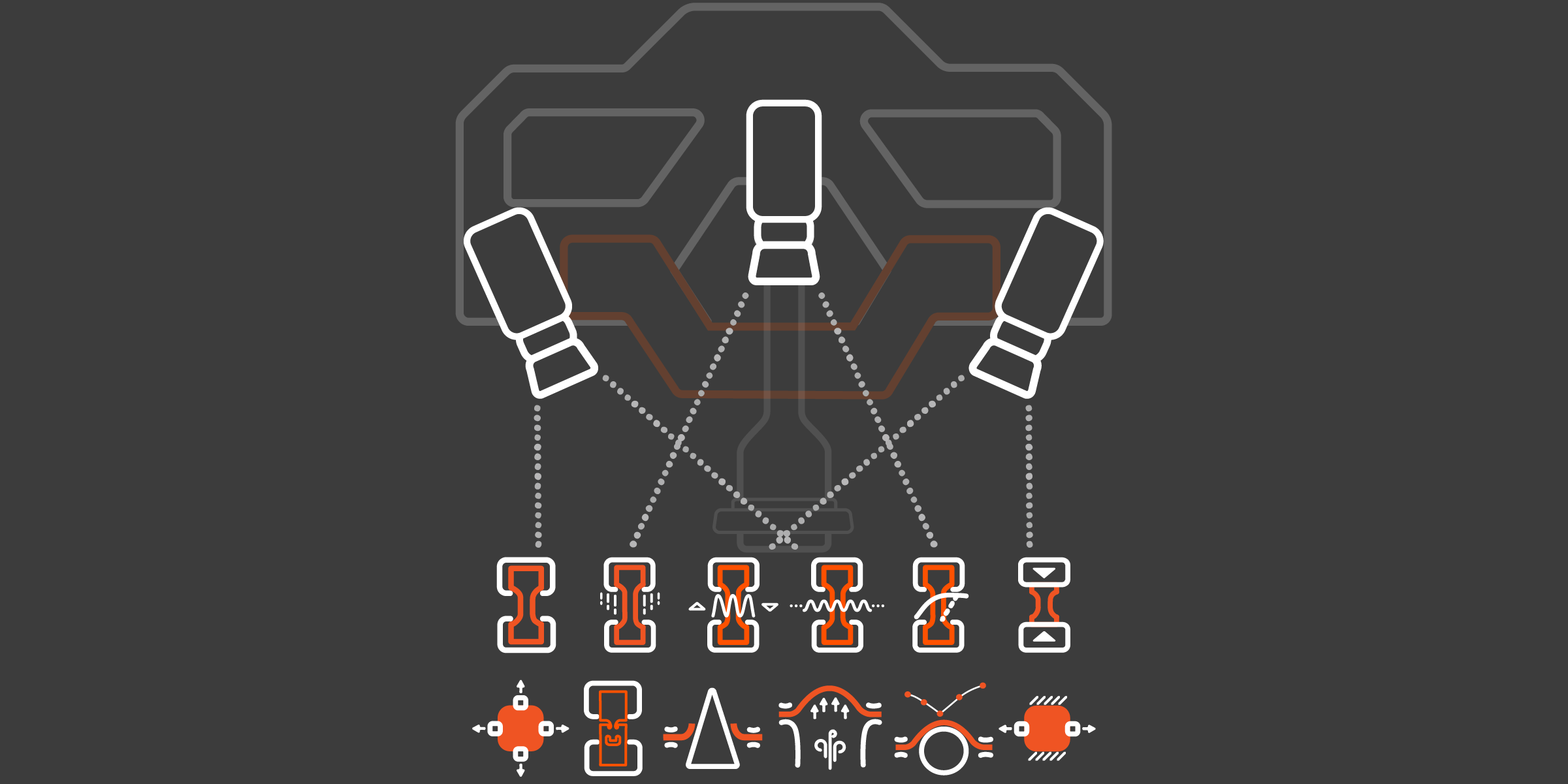

01

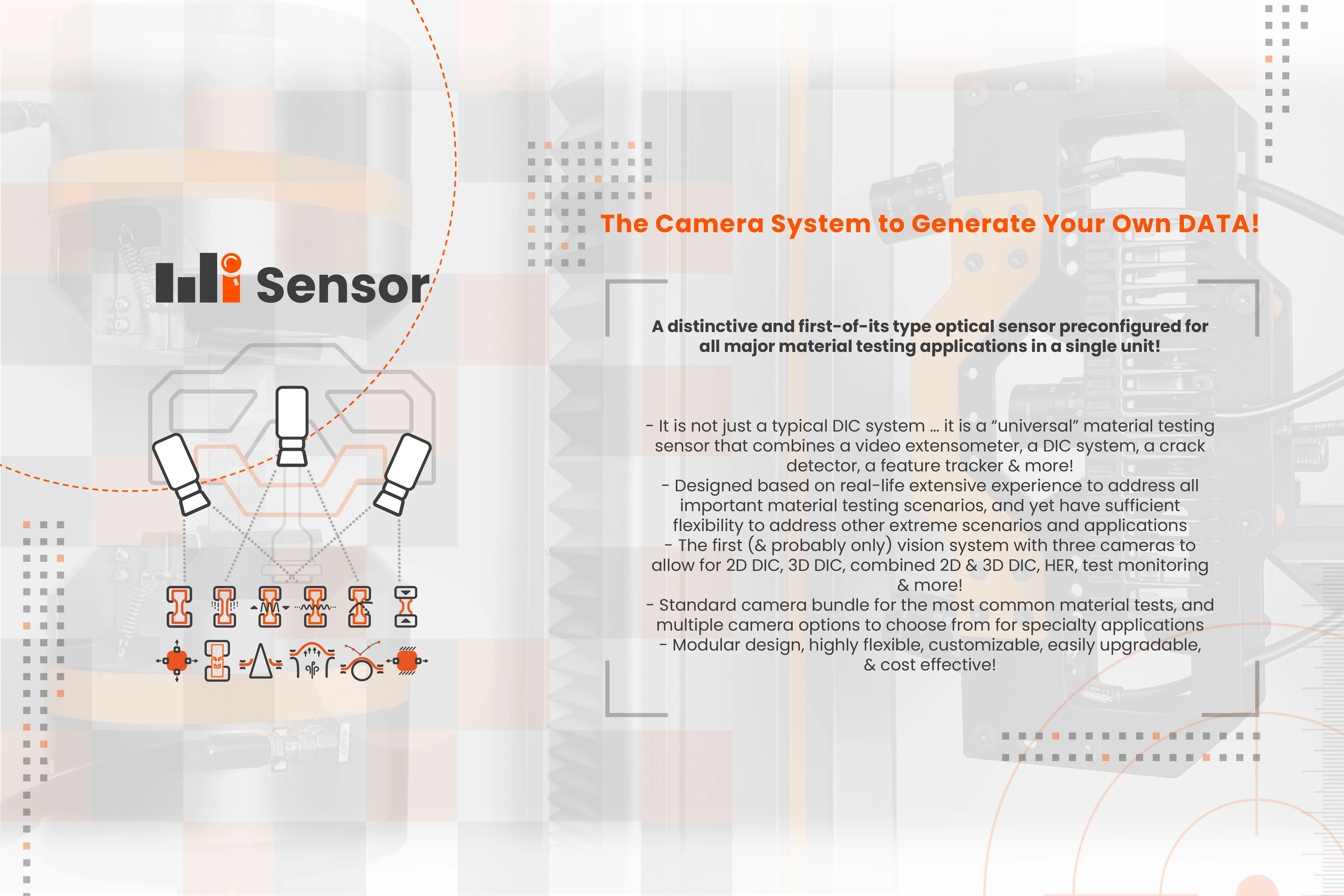

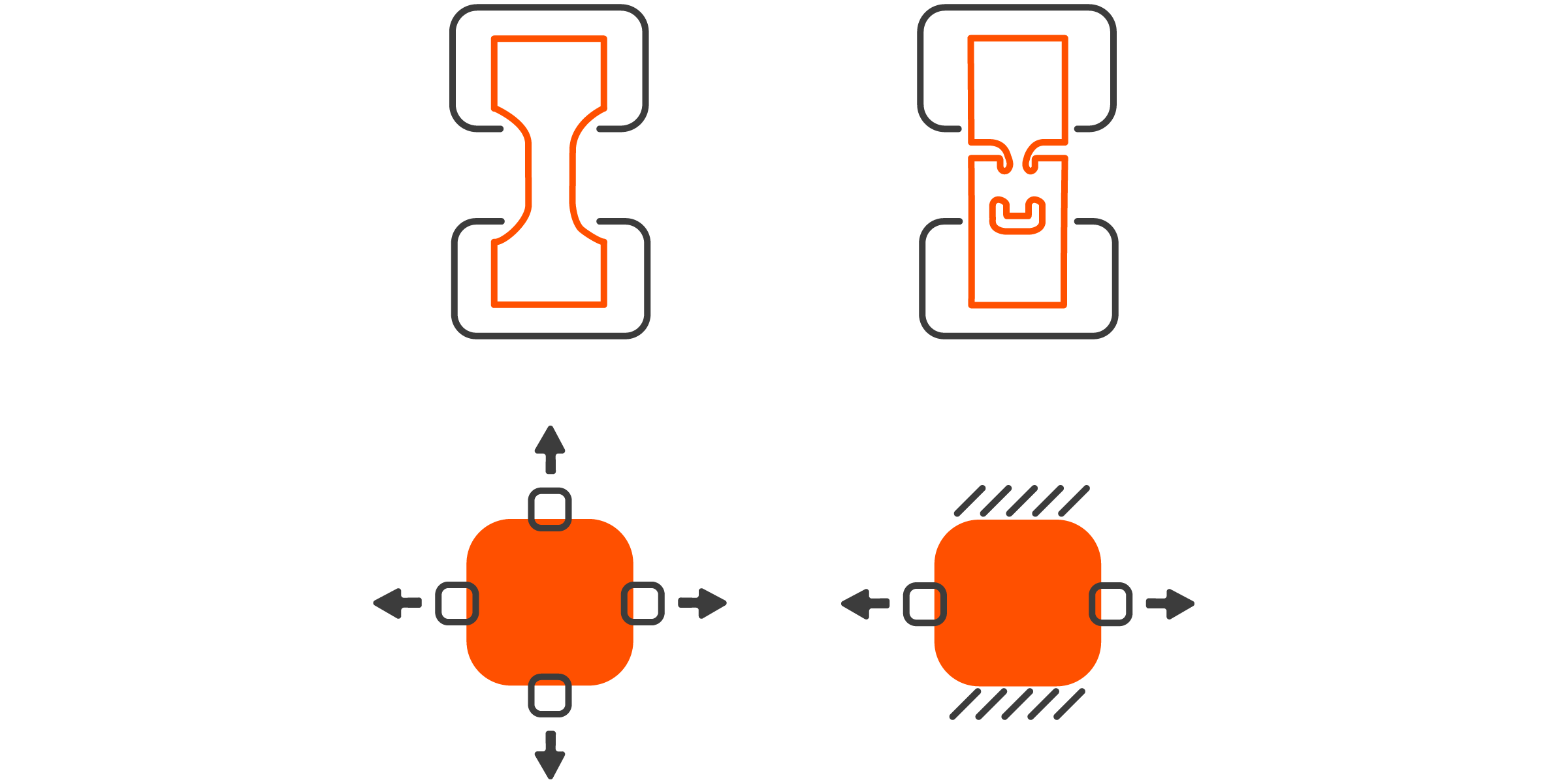

Not just simple uniaxial tension data … but a wide variety of multiaxial and complex loading paths that truly mimic the actual loading conditions a material undergoes in practical applications!

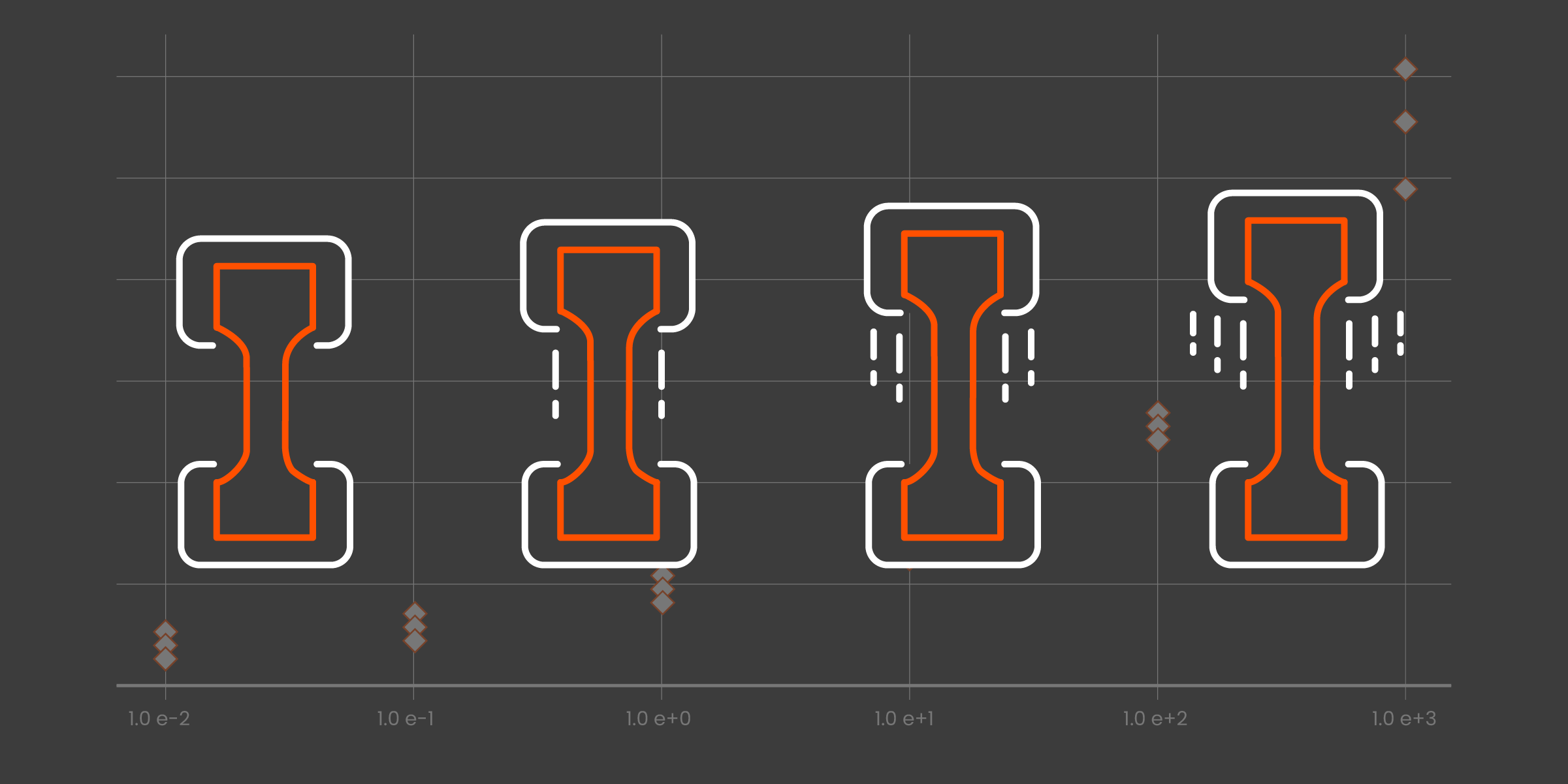

02

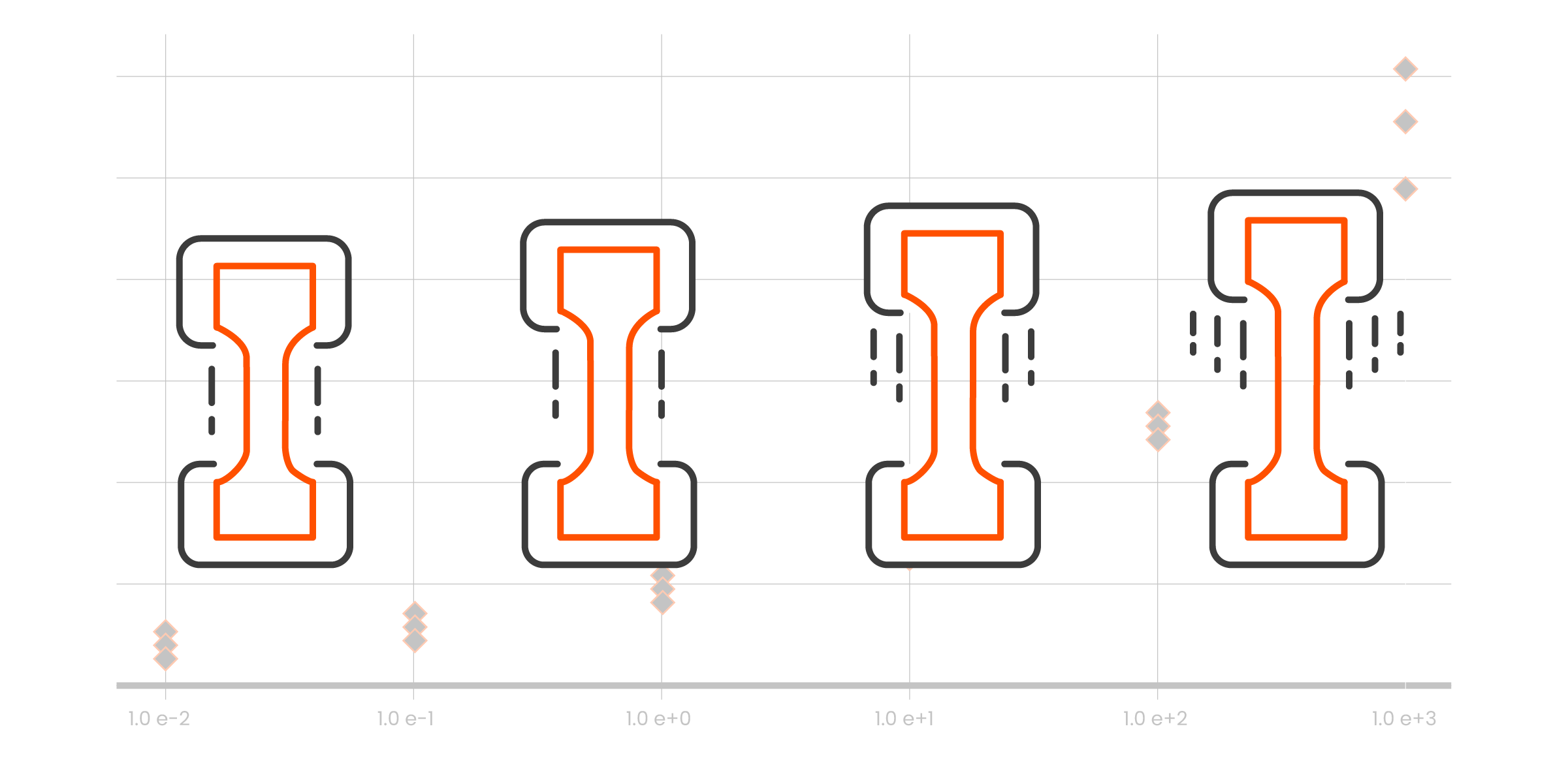

Not just idealistic quasi-static loading conditions … but we go into the intermediate and high strain rate territories to reflect practical manufacturing and crash conditions!

03

Not simple extraction from universal testing machines … but DATA entirely based on digital image correlation (DIC), image processing algorithms & non-contact optical sensors!

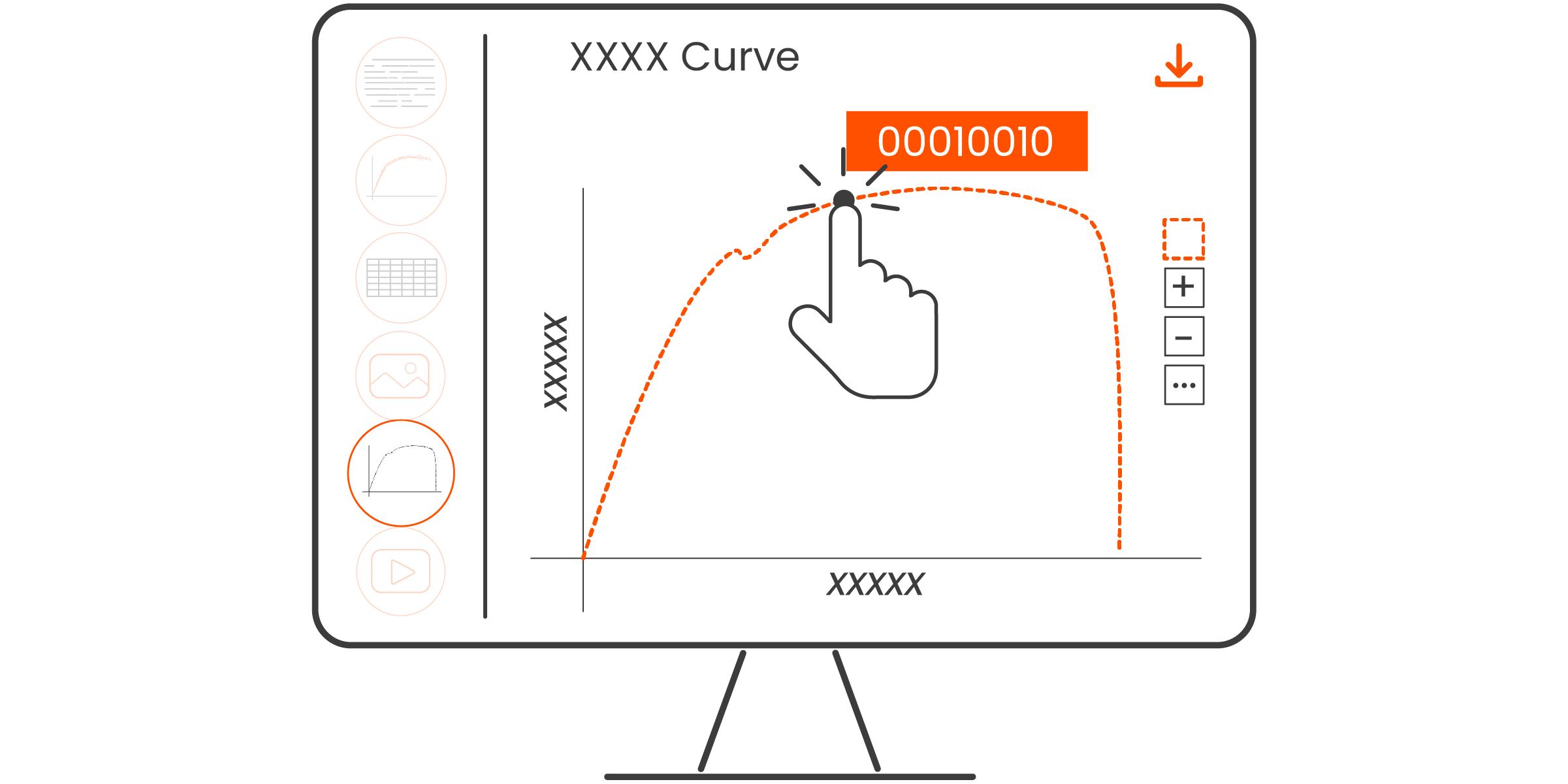

04

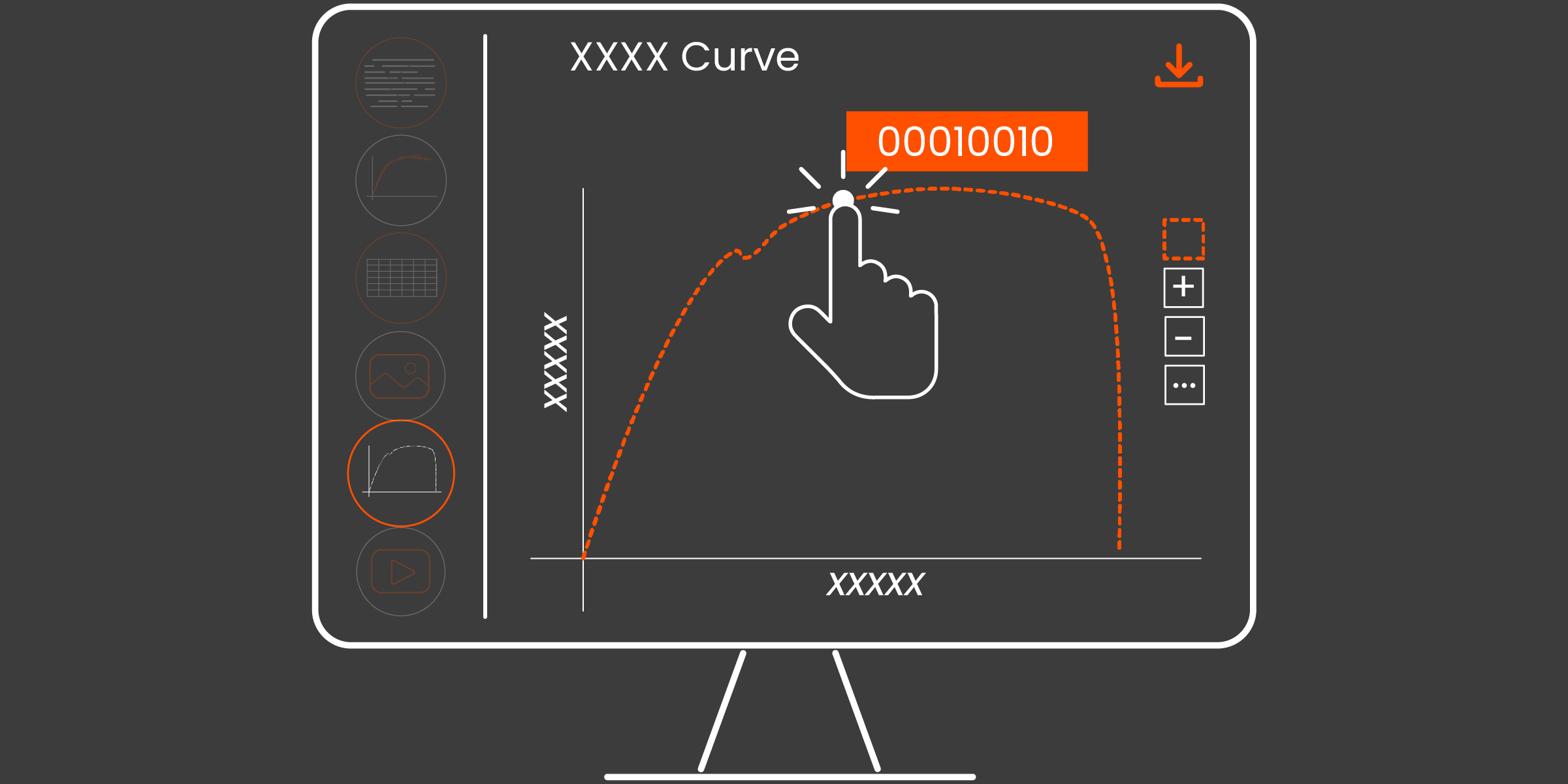

Not just conventional DATA format (discrete numbers) … but additional unique formats to allow you to interact with the DATA! Dynamic files with tunable tools & curves, interactive DIC surface strain maps, and comprehensive DIC videos!

05

Not just conventional DATA files … but rather comprehensive “DATA packages” that encompass detailed DATA sets, pre-configured plots, organized summary tables of properties & failure strains & ready-to-use FEA input parameters!

06

Not just simplistic outputs … but rather thorough packaging of DATA with quality of presentation and attention to detail that is truly bordering on obsession! Are you ready to try something truly unique?